Electric Yard Trucks Are Delivering Lower TCO

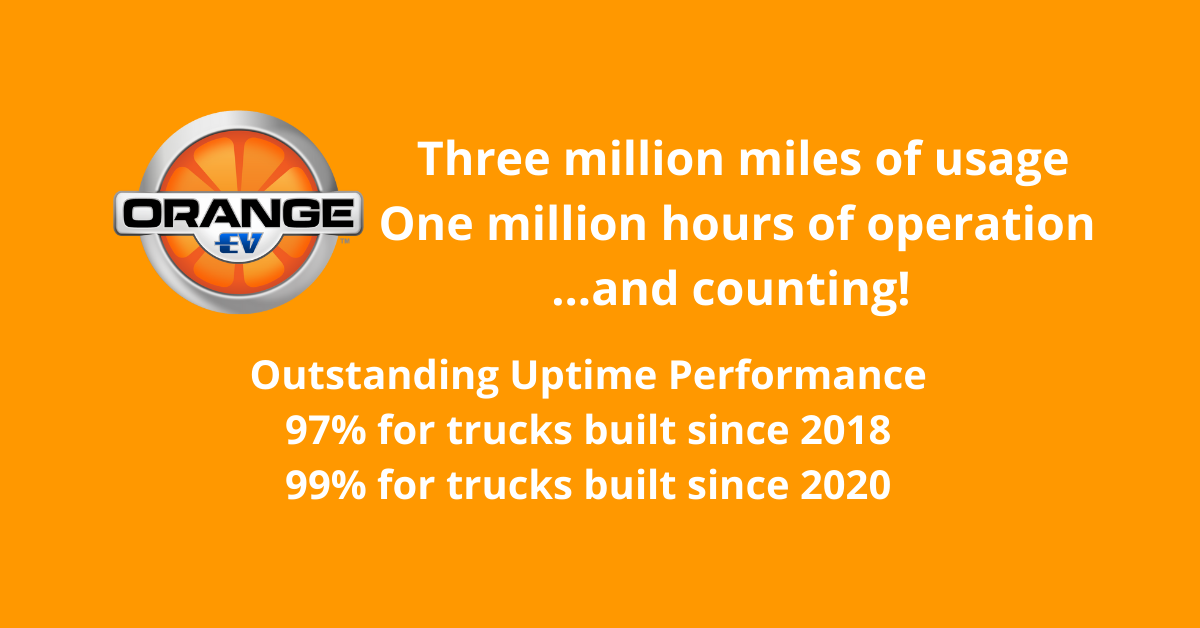

While over-the-road heavy duty electric trucks are still being developed, pure electric yard trucks are already ramped up and providing well-established benefits: they’re more comfortable to drive than their diesel counterparts, have lower operating costs, and produce zero emissions. And hard data from these deployments prove that electric yard trucks can pencil out in short order, even without incentives. Yard trucks are generally off-road vehicles that work at speeds under 25 mph moving trailers and shipping containers. These vehicles typically operate within the confines of a yard focused on warehousing, distribution, manufacturing, or intermodal transfer. In these scenarios, diesel yard trucks are particularly inefficient, while the low-speed operation, frequent starts and stops, and close proximity to charging stations are an excellent fit for battery electric yard trucks. Calculating payback speed – the length of time needed to recoup the higher up-front cost of electric over diesel – depends on each fleet’s unique duty cycle and cost structure. The primary variables include: Taking these variables into account, electric yard trucks have already been delivering a lower total cost of ownership (TCO), even at moderate-use sites, and even without incentives. Payback can be three to four years at moderate-use sites and even faster for heavy-use operations. Here’s a simple scenario to illustrate this point: Let’s start with the upfront cost. A fleet can purchase a new Tier 4 diesel yard truck for $120,000, while the cost of an electric yard truck could be $270,000, including charging and infrastructure costs. With the right charger selection, most sites will already have the electrical capacity required for initial electric yard truck deployments, so these locations will require minimal additional infrastructure for charging. The incremental upfront cost of electric over diesel is $150,000 per truck. Now we’ll add the fuel cost. Electricity costs much less than diesel, and EVs are much more energy efficient than internal combustion engines. These advantages result in an 85%-90% reduction in fuel expenses. In a moderate two-shift operation, one diesel yard truck can operate 4,000 hours per year, generating diesel fuel costs of $28,000 (at 1.75 gal/hr and $4.00/gal) compared to an electricity cost of $3,360 for the electric yard truck (at 7 kWh/hour and $0.12/kWh). The fuel savings adds up to $24,640 per year, in favor of the electric yard truck. If we look at a busier use case and more recent diesel prices, such as 6,000 hours per year and $5.50/gallon for diesel in California, the annual fuel cost savings would be over $50,000. Operations like this will see even greater savings and faster payback. , Bolthouse Farms concurrently deployed new electric and diesel yard trucks. This direct, 2-year comparison revealed an 80% reduction in M&R costs with electric yard trucks, generating net savings of $3.15/hour. Sound too good to be true? When you think about where the savings come from, it makes perfect sense: M&R savings for one electric yard truck would equal $12,600 per year at a $3.15/hour reduction over 4,000 hours of operation. Note that this case study used internal labor rates. Where outsourced maintenance costs more, savings will be even greater. Some fleets have reported M&R savings of up to $6.50/hour. In the same case study referenced above, Bolthouse documented a 75% reduction in downtime with electric yard trucks. It’s not uncommon to hear of diesel yard trucks being down 20% of the time, while Orange EV electric yard trucks average just 1-2% downtime. This dramatic reduction in downtime is achieved through a combination of more reliable parts, avoiding repair-prone diesel components, and speedy repairs done on-site using a fleet of mobile service technicians. The direct cost of diesel downtime repairs is captured in the M&R budget, but additional expenses are incurred from lost productivity, late deliveries, and the need to either rent replacement trucks or purchase and manage more diesel trucks than strictly necessary, to cover for diesel yard trucks stuck in the shop. Add to this the many diesel-related costs that are minimized or eliminated with electric: diesel fuel management, emissions- or spill-related fees and fines, hazmat cleanup, liability and workers’ comp claims, etc. These savings can conservatively total at least $10,000 per year, in favor of electric yard trucks. Diesel yard trucks are hard on drivers due to the drivers’ continuous exposure to: All of these impacts are eliminated with electric trucks, increasing driver health and well-being while positively influencing productivity, job satisfaction, and employee retention. Reduced noise and emissions also benefit other site personnel and the surrounding community. These soft dollar savings are real, but harder to quantify, so we’ll leave them out of this simple calculation. In this example, the savings from using electric yard trucks add up to $47,240 per year, giving a payback of 3.2 years for the $150,000 incremental cost. Making small changes to this scenario will increase the savings realized and further accelerate the payback: Of course, this is a simplistic view. From a cost basis perspective, it’s important to factor in asset depreciation and interest, warranties, and site-specific data when available. Will the payback for electric yard trucks be about three years in every case? No. But the savings and benefits are proven and real. Taking the time to run the numbers to guide your decision can result in a competitive advantage, a safer, healthier work environment, and meaningful, measurable steps towards sustainability goals. Even lower-use operations can pencil out, and when budgets don’t have room for the higher up-front cost of electric yard trucks, leasing can be a very helpful solution. Incentives can also help defray costs, but they come with uncertainty, restrictions, and quite often, a long timeline. Competition is increasing for grants and vouchers, and if awarded, fleets may have to wait six months or more to deploy their new trucks, losing out on months of operational savings and emissions reductions. Independent studies also confirm the real-world savings reported by fleets operating electric yard trucks. According to the December 23, 2021 release of “Charging Forward: BEV & FCEV Forecast and Analysis, 2nd Edition” by ACT Research, battery-electric powered yard trucks in 2021 provided a better TCO than diesel-powered versions. Electric yard trucks have proven they can do the job, with over 400 trucks deployed across the U.S. in harsh climates, 24×7 operations, and all sectors of goods movement. Given their compelling benefits and lower total cost of ownership, electric yard trucks are well on their way to becoming the industry standard. The time to switch is now. Published: { "@context": "", "@type": "ImageObject", "contentUrl": "", "name": "Multiple Orange EV Yard Trucks", "description": "Orange EV pure electric yard trucks", "provider": { "@type": "Organization", "name": "Orange EV", "url": "", "image": "" } } { "@context": "", "@type": "WebPage", "mainEntityOfPage": { "@type": "WebPage", "@id": "" }, "headline": "Electric Yard Trucks Are Delivering Lower TCO, Even Without Incentives", "image": [ ], "datePublished": "2022-05-02T12:47:37+00:00", "author": { "@type": "Organization", "name": "Orange EV" }, "publisher": { "@type": "Organization", "name": "Orange EV", "logo": { "@type": "ImageObject", "url": "" } }, "description": "The electrification of the trucking industry is ramping up, and while the prospect of electric over-the-road fleets crisscrossing the nation’s highways is exciting, it’s definitely a work in progress. Many questions remain to be answered including range, charging options, performance in extreme temperatures, battery pack weight, and time required to achieve payback.", "keywords": "Electric Yard Trucks Are Delivering Lower TCO, Electric Yard Trucks, Electric Trucks, Pure Electric Yard Trucks, Yard Truck, Electric Yard Truck, Yard Trucks, diesel yard trucks, electric trucks, orange evelectric vehicle, EV" }