LFP Battery Chemistry

Why LFP Battery Chemistry Is Superior for Electric Yard Trucks

Lithium iron phosphate offers significant advantages for these powerful tractors. Orange EV’s president explains.

As featured in Battery Tech Online

Once a freight-moving company has chosen to add electric yard trucks to its fleet, there is one more key decision it needs to make—selecting the right battery chemistry. Electric yard trucks represent a big investment in a long-life asset, so prospective buyers want to be sure that they choose the battery chemistry that will perform the best; involve the least amount of complexity; and last the longest.

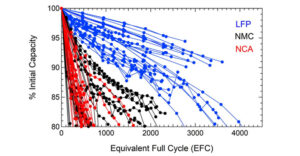

Discharge capacity retention for all LFP (in blue), NMC (black), and NCA (red) cells relative to the initial capacity of each individual cell. Circles are data points from the capacity check at the conclusion of each round of cycling and lines are a guide for the eye.

There are several different battery types available. Each has its strengths and weaknesses. But for the specific use case that electric yard trucks experience, there is one battery chemistry that tops them all. That battery chemistry is Lithium Iron Phosphate, usually abbreviated as LFP.

A recent apples-to-apples study, performed at the Sandia National Laboratory, has shown the superiority of LFP batteries for the unique situation that yard trucks encounter. Here are the many benefits of LFP compared to its main competitors, Nickel Manganese Cobalt (NMC) and Nickel Cobalt Aluminum (NCA):

LFP provides longer-lasting performance

Lithium Iron Phosphate (LFP) batteries have a longer lifespan than NMC and NCA batteries. According to a study by the US Department of Energy, LFP batteries can last up to 10 years, while NMC and NCA batteries have a lifespan of 5–7 years. This makes LFP batteries a more durable and reliable option for EV manufacturers.

Other benefits of LFP include retaining a higher percentage of their charge as they age: LFP frequently retains 90% of its capacity later in its lifespan compared to NMC, that commonly drops below 80%. LFP also shows minimal degradation from being repeatedly charged from 0% to 100%, whereas NMC batteries are subject to significant degradation from this type of charging.

LFP is safer, less prone to overheating and fires

You may have heard of “thermal runaway,” which occurs when an electric vehicle’s battery overheats, resulting in a potential fire or even an explosion. These tend to occur with NMC batteries, which run much hotter during both normal operation and charging, especially fast charging. NMC battery packs will typically have complex cooling systems to keep their operating temperatures under control, thus preventing thermal runaway. These packs may also need to have ceramic insulators placed between the cells to manage the heat: LFP packs do not need this.

LFP batteries have a different, more stable chemistry which makes thermal runaway much less likely, even during fast charging. A contributing factor is that LFP batteries have a much higher flashpoint (518ºF vs. 419ºF for NMC), which significantly reduces the possibility of any thermal events.

LFP is more environmentally friendly

The simple fact is that LFP batteries, by definition, do not contain any cobalt or nickel. NMC and NCA batteries require both of these toxic metals to function. In additional to their harmfulness to the environment, cobalt has its own dirty little secret: The fact that it is often mined in countries like the Democratic Republic of Congo, where unethical practices like child labor are used to extract it from the earth. LFP batteries are also easy to recycle at the end of their lifespan.

LFP is currently being used by Tesla, Orange EV, and other EV manufacturers

The use of LFP batteries has become commonplace in China, the world’s largest electric vehicle (EV) market. Tesla embraced the use of LFP in many of its Chinese vehicles, along with many other manufacturers in that market. In fact, as of September 2022, LFP batteries were being used in 31% of all electric passenger vehicles in China. Other global automakers have awakened to the benefits of LFP batteries and will be adding them to their EVs within the next model year. Further improvements in LFP chemistry, battery design, and overall EV efficiency will ultimately make LFP range-competitive with NMC and NCA in the consumer EV marketplace, too.

There are some use cases where NMC and NCA might be a better option

Sure, there are some situations where NMC or NCA batteries might make more sense. These include vehicles where weight or space is at a premium and the battery technologies available cannot meet the range requirements of the application. This can include passenger cars, and over-the-road trucks, where ultimate range is an important factor and once-a-day charging is the norm. Of course, with long-haul trucks, the major weight of the high-mileage battery pack cuts into load capacity, so there is some more work to be done for that use case where the need for maximum energy density is a good tradeoff for the shorter life and higher complexity (think cost and downtime).

LFP: Simply the superior choice

When it comes to yard trucks, where you are never far from a charger, the weight and space available can easily accommodate the battery pack size to run 24×7 with a moderate level of charging, and you can and should top up your charge during breaks and meals, the overall performance of LFP outshines its rivals. At Orange EV, we didn’t just grab some existing technology off the shelf. We picked the right battery chemistry for the very specific requirements of a yard truck, designed our yard truck around it, and are very proud of the results. Even the very first Orange EV yard trucks, deployed over 7.5 years ago, are all still running well on their original LFP battery packs.

For all the reasons that matter to operators of electric yard trucks, LFP is the superior choice when selecting your battery chemistry. LFP batteries last longer, are safer to operate, can be repeatedly charged to maximum capacity without shortening their lifespan, and are better for the environment. This all adds up to the lowest possible operating costs over the longest possible lifespan. When combined with the many benefits of electric yard trucks over their diesel counterparts, LFP battery chemistry makes the decision to go electric even easier!

Kurt Neutgens co-founded Orange EV and leads design, production, service, and technical support. With a career focused on vehicle design and improvement, Kurt brings 17 years of experience from Ford Motor Company in 20+ positions across powertrain, calibration, quality, NVH, and program management. www.orangeev.com

Published: July 13, 2023/Battery Tech Online/